FEATURES

PERFORMANCE = MORE USABLE POWER

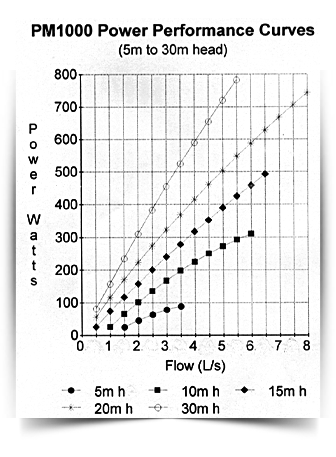

Maximum efficiency is achieved using our advanced permanent magnet alternators in combination with the unique Platypus impulse runner. Maximum output from low and high flow situations.

RELIABILITY & DURABILITY

Materials of the highest quality are used in construction eg. marine grade 316 stainless steel runner and marine grade aluminium casing to resist abrasion and corrosion. Heavy duty bearing enable us to guarantee 5 years bearing life . No brushes is another feature which means uninterrupted electricity and low maintenance.

Automatic shut down through the control board protects connected electrical equipment and the generator from over-voltage.

SIMPLICITY

A single, easily inter-changeable nozzle delivers the full range of flows. In combination with the Platypus impulse runner, maximum output from seasonal flows can be maintained. Simple installation is via a single 2″ table D flange.

INNOVATIVE CONTROLLER

The heart of the PM1000 Charge Control module is the innovative and proven B-SR50 constant voltage taper current regulator. It allows adjustable boost for maximum battery life. The Charge Control Module comes wired complete with finned dump load elements, circuit breaker, battery voltage meter, charge current meter and dump amp meter for easy installation.

TOUGH MACHINES BUILT FOR REMOTE PLACES

Built to be relied upon in remote locations and withstand the harsh Australian environment.

Specifications

| MODEL | PM1000 |

| Generator maximum output | 750 W |

| TURBINE | |

| Runner | Platypus 316 Stainless Steel Impulse |

| Runner jet circle diameter (mm) | 100 |

| Minimum operating head(m) | 5 |

| Maximum operating head (m) | 80 |

| Minimum flow rate (l/sec) | 0.5 |

| Maximum flow rate (l/sec) | 7.5 |

| Turbine Casing | Marine grade Aluminium-powder coated |

| Standard nozzle type | Nylon conical x 1 |

| Nozzle diameter range (mm) | 10 to 24 @ 2 mm intervals |

| Inlet pipe connection | 2 inch table D flange |

| GENERATOR | |

| Alternator | Permanent magnet brushless |

| Voltage | 12, 24 & 48 |

| Generator to turbine coupling | Direct |

| SYSTEM CONTROL | |

| Charge control regulator | Electronic Constant Voltage Taper |

| Current B-SR50 or BX-SR50 | |

| Cubicle | Steel enclosure IP55 (Powder coated) |

| Voltage (V) | 13 – 70 |

| Voltage regulation | |

| (% of rated voltage) | +/- 1% |

| Power rating (W) | 360 at 12V |

| 750 at 24 & 48V | |

| Dump load elements | Resistive solid core (finned air cooled) |

| Number of elements | 1 for 1 to 400 watts (B-SR50) |

| 2 for 401 to 750 watts (BX-SR50) | |

| SYSTEM MONITORING | |

| Battery Charge Current | Analogue 0 to 30 Amp at 12 & 24V |

| Analogue 0 to 15 Amp at 48V | |

| Dump Load Current | Analogue 0 to 30 Amp at 12 & 24V |

| Analogue 0 to 15 Amp at 48V | |

| Battery Voltage | Analogue 0 to 15V at 12V |

| Analogue 0 to 30V at 24V | |

| Analogue 40 to 60V at 48V | |

| Battery Status | Light emitting diode (LED) |

| Pressure gauge | 800 kPa (oil damped) |

| SYSTEM PROTECTION | |

| Overcurrent | Circuit breaker |

| DIMENSIONS & WEIGHTS | ||

| Item | PM1000 | B-SR50 Governor |

| Size (mm) (LxDxH) | 340x340x285 | 375x210x460 |

| Weight (kg) | 18 | 10.3 |

| OPTIONS | ||

| Discharge pit with base plate | Polypropylene pit & Galvanised steel | |

| base plate | ||

| Dimensions (mm) | 565 L x 565 D x 320 H | |

| Filter | ||

| Electric solenoid valve | ||

| Hot water element for gravity fed system |